-

+86-(0)573-87985868

-

+86-(0)573-89237968

-

-

NO.11 Hongqi Road, warp knitting industrial park of Haining City, Zhejiang Province, China

Web Menu

Product Search

Language

Exit Menu

News categories

Product categories

Exhibition Information

Opaque White Printable Substrate Film for Solvent Printing

Opaque white printable substrate films are gaining popularity in the printing industry, especially for solvent printing applications. These films offer a solid, non-translucent background, allowing vivid colors and sharp details to stand out on various surfaces. Ideal for a wide range of applications, from packaging and labeling to outdoor signage, these films are versatile and essential in industries that require high-quality, durable printing materials.

1. What is an Opaque White Printable Substrate Film?

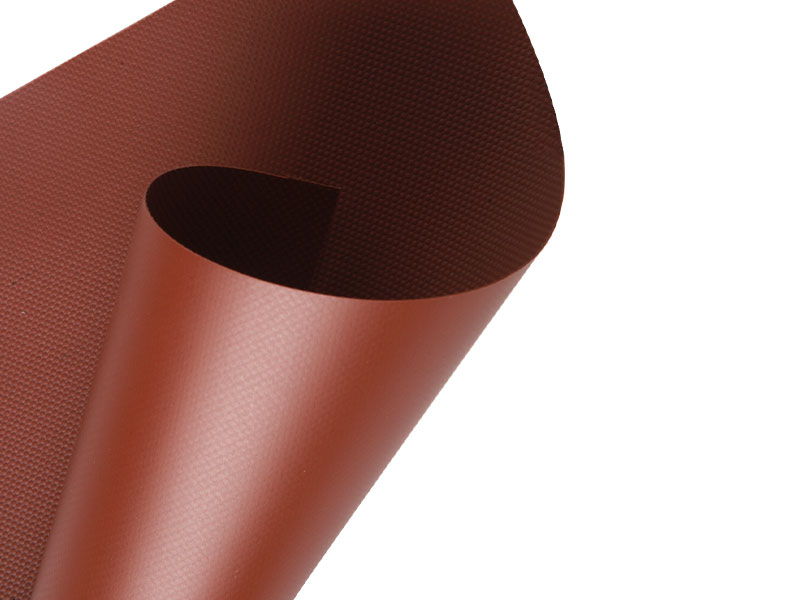

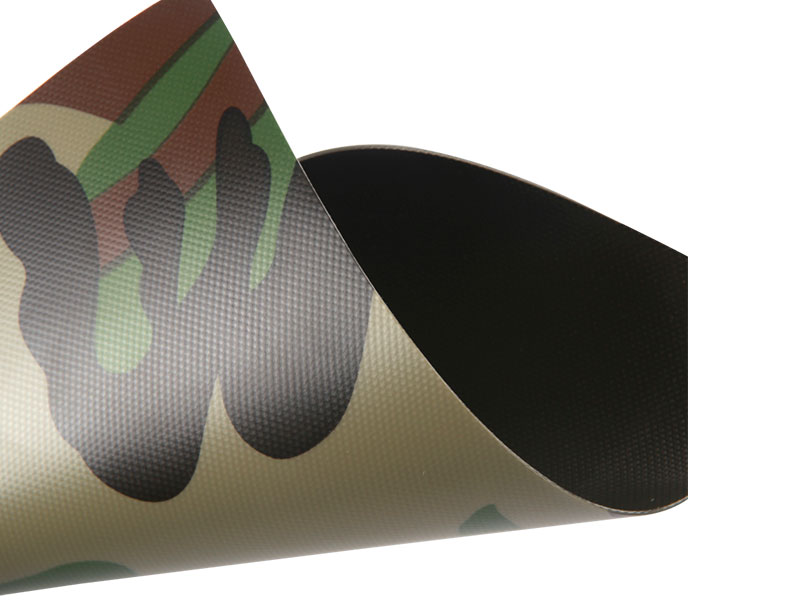

Opaque white substrate films are specialized materials designed for printing applications that require a solid white background. This opacity ensures that the colors printed on the film appear vibrant and clear without interference from the surface underneath. The film’s surface is engineered to work well with solvent-based inks, which provide excellent adhesion, color fastness, and durability.

Material Composition: These films are often made from materials like polypropylene (PP), polyvinyl chloride (PVC), or polyethylene (PE) that enhance opacity and durability.

Surface Treatment: The films are treated or coated to create a receptive surface for solvent inks, improving print clarity and image sharpness.

2. Advantages of Opaque White Films in Solvent Printing

Opaque white substrate films bring several benefits to solvent printing:

Enhanced Color Vibrancy: The white background allows colors to appear more vibrant, providing a visually appealing print with high contrast and sharp detail.

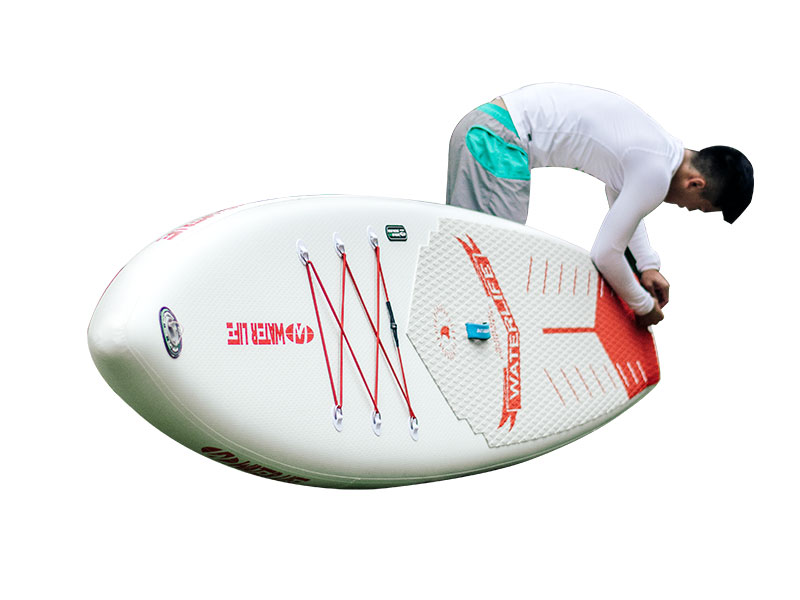

Versatility: These films can be used for various applications, including banners, window displays, labels, and vehicle wraps, due to their durable and flexible properties.

Weather Resistance: Opaque films are usually resistant to UV radiation, moisture, and temperature changes, making them ideal for outdoor applications.

Durability: They offer a strong substrate that withstands environmental factors, reducing the need for frequent replacements.

3. Solvent Printing and Its Compatibility with Opaque White Films

Solvent printing is a process where solvent-based inks are used to adhere to various surfaces, creating vibrant, long-lasting images. These inks are water-resistant and highly durable, making them suitable for demanding applications such as outdoor signage and packaging.

Key Compatibility Factors:

Ink Adhesion: Solvent inks adhere well to treated opaque films, ensuring that the print does not peel or fade easily.

Drying Time: Solvent inks dry relatively quickly on treated films, reducing smudging and improving efficiency in high-speed printing applications.

Environmental Compatibility: Both the ink and substrate are often designed to withstand various environmental stresses, which is crucial for outdoor applications.

4. Applications of Opaque White Printable Films

Opaque white printable substrate films are versatile, serving a range of industries:

Outdoor Advertising: The films are commonly used in billboards, banners, and posters that require high visibility and durability in outdoor environments.

Packaging and Labeling: Many food and consumer goods companies use opaque white films for labels, as they provide excellent adhesion and high-quality print for branding.

Retail Displays: Point-of-purchase (POP) displays often use these films to create high-impact graphics that attract consumers in-store.

Automotive and Fleet Graphics: Vehicle wraps benefit from the durability and clarity of solvent-printed opaque films, which can withstand exposure to sunlight, rain, and physical wear.

5. Environmental Impact and Sustainability Considerations

While opaque white printable films and solvent-based inks are effective for many applications, there are environmental considerations. Solvent inks, for example, contain volatile organic compounds (VOCs) that can be harmful if not managed properly. Some manufacturers are exploring eco-solvent inks that have lower VOC levels, which can reduce environmental impact.

Recycling or repurposing these films can also be challenging due to their composite materials and coatings. However, the durability of these films often means a longer lifespan, which can offset some environmental concerns by reducing the frequency of replacements.

6. Choosing the Right Opaque White Substrate Film for Your Project

When selecting an opaque white substrate film for solvent printing, consider the following factors:

Thickness and Durability: Thicker films provide greater durability but may be less flexible. Choose a thickness based on your specific application.

Compatibility with Solvent Inks: Ensure the film is treated for optimal ink adhesion and drying.

Weather Resistance: If the film will be used outdoors, check for UV and moisture resistance.

Print Clarity and Color Performance: Choose a film that enhances print clarity and color vibrancy for high-impact graphics.

UV and Eco-Solvent Printing Backlit Fabric Film for Advertising: Innovation, Application and Advantages

Printed White PVC Vinyl Stretch Ceiling Film: An Innovative Choice for Modern Interiors

related products